Products / Bentonite Grinding Plant

Grinding Plants for Fine Grinding

Calcite Grinding Plant

Bentonite Grinding Plant

Bentonite Grinding Plant

Coal Grinding Plant

Coal Grinding Plant

Grinding Plants for Raw Material Preparation

Calcite Raw Material Preparation Plant

Grinding Plants for Raw Material Preparation

Calcite Raw Material Preparation Plant

Coal Raw Material Preparation Plant

Coal Raw Material Preparation Plant

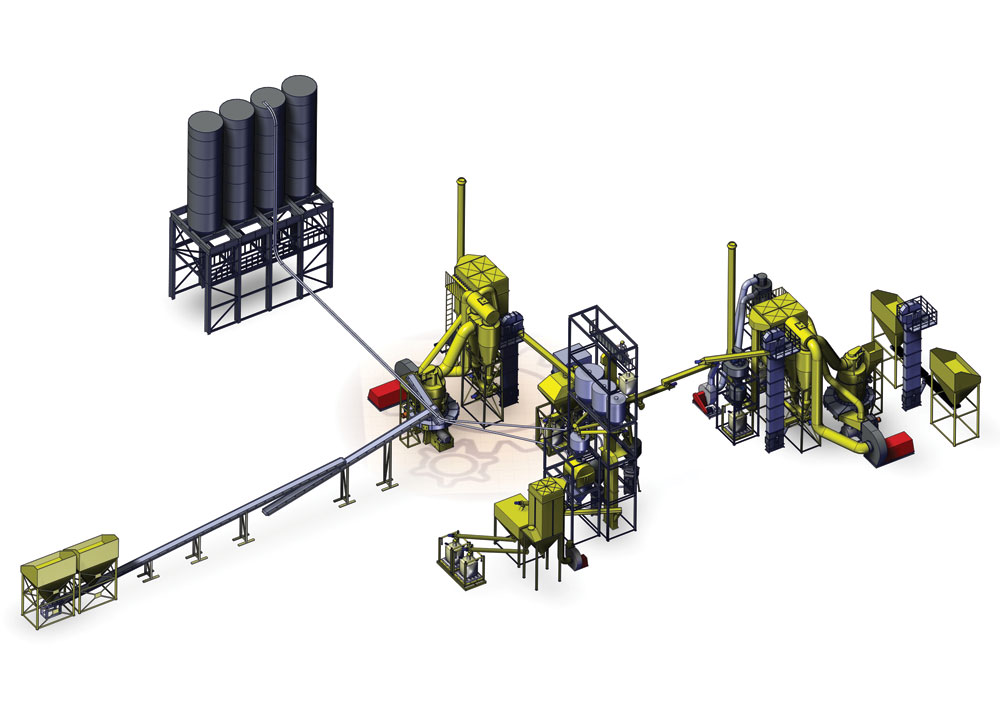

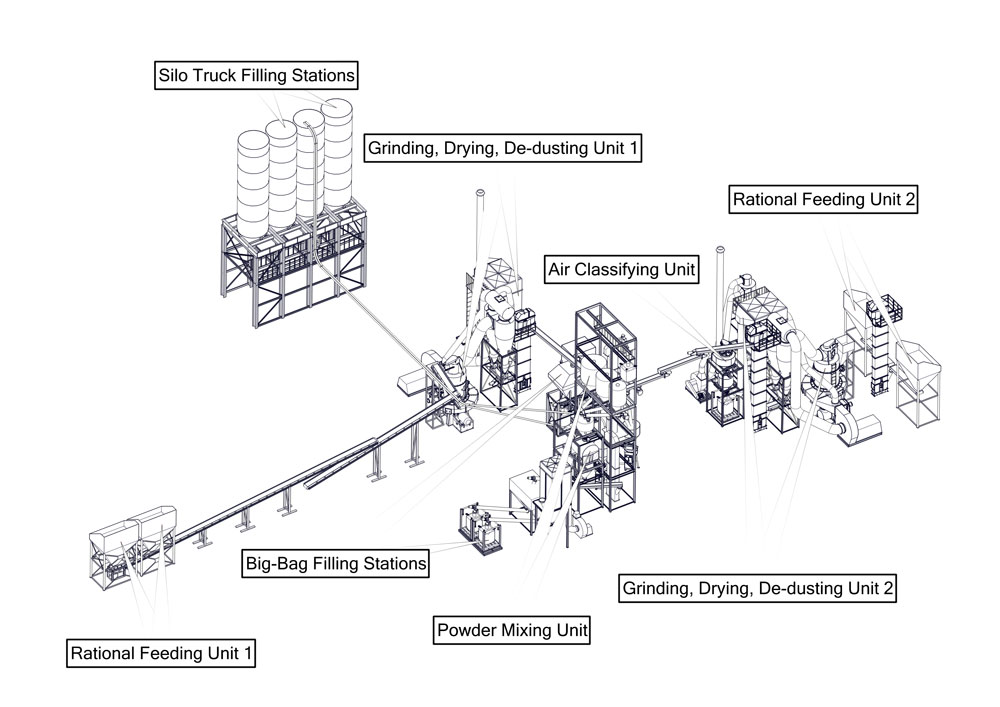

Bentonite is used in foundry and drilling industries extensively. Along with the high free silica content, bentonite itself is an abrasive mineral. It has a high sensitivity of moisture which makes difficult even feeding of the material. High moisture content reduces the capacity and can totally prevent grinding at some level. By having an experience on the field of grinding bentonite for more than 35 years, CMS is a solution partner for leading bentonite manufacturers in Turkey and in the world.

Descriptions about the demonstrated bentonite plant;

- Bentonite is fed from the feeding silo into the system. Coal can also be fed together with the bentonite rationally.

- Material ground in pendulum roller mill (STD series) passes through the mill classifier and can be directed to powder mixing unit, big-bag unit or silo truck unit.

- During the grinding operation, drying is applied simultaneously in order to increase the capacity. By the help of integrated automation system, temperature values can be determined on two points. Hence the quality of the bentonite is assured by preventing overheating.

- By adjusting the rpm. of the mill classifier, upper particle size is under control.

- Automation management is done via central processing computer with SCADA. Process flow can be managed by using a mimic diagram. Simultaneous changes can be made, reports can be obtained, manual controls can be applied. Remote connections are available via ethernet module. Standard recipes can be formed for various customers.