Products / Calcite Grinding Plant

Grinding Plants for Fine Grinding

Calcite Grinding Plant

Bentonite Grinding Plant

Bentonite Grinding Plant

Coal Grinding Plant

Coal Grinding Plant

Grinding Plants for Raw Material Preparation

Calcite Raw Material Preparation Plant

Grinding Plants for Raw Material Preparation

Calcite Raw Material Preparation Plant

Coal Raw Material Preparation Plant

Coal Raw Material Preparation Plant

Fine calcite has a wide area of usage including paint, paper, glass, powder gypsum, power, fertilizer etc. industries. By the means of producing innovative solutions for these industries, CMS is a solution partner of leading calcite manufacturers in Turkey and in the world.

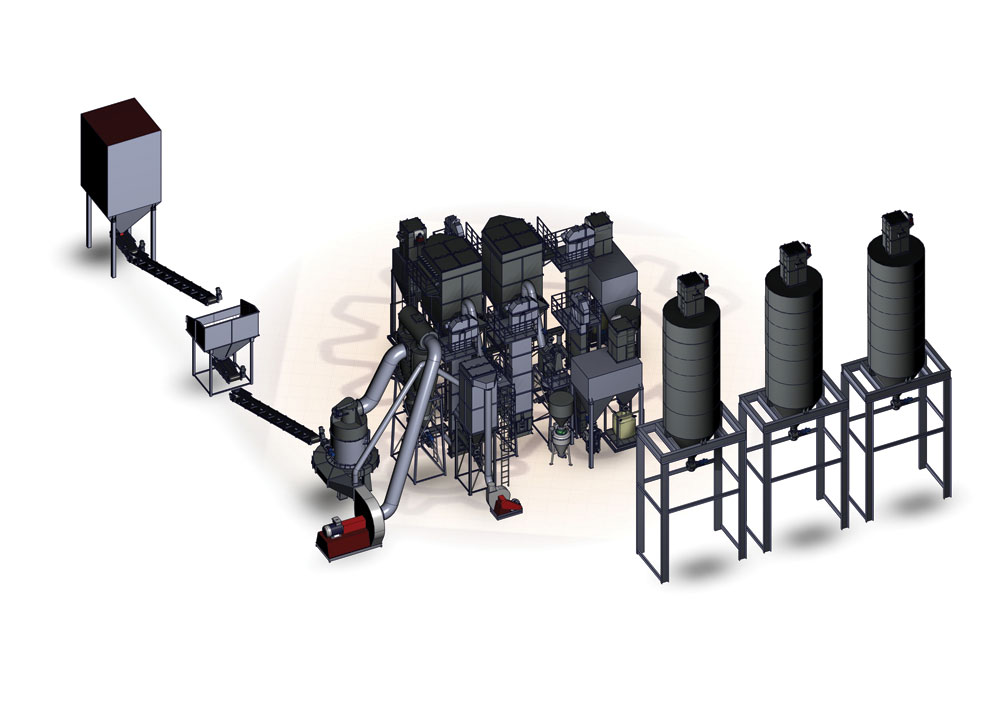

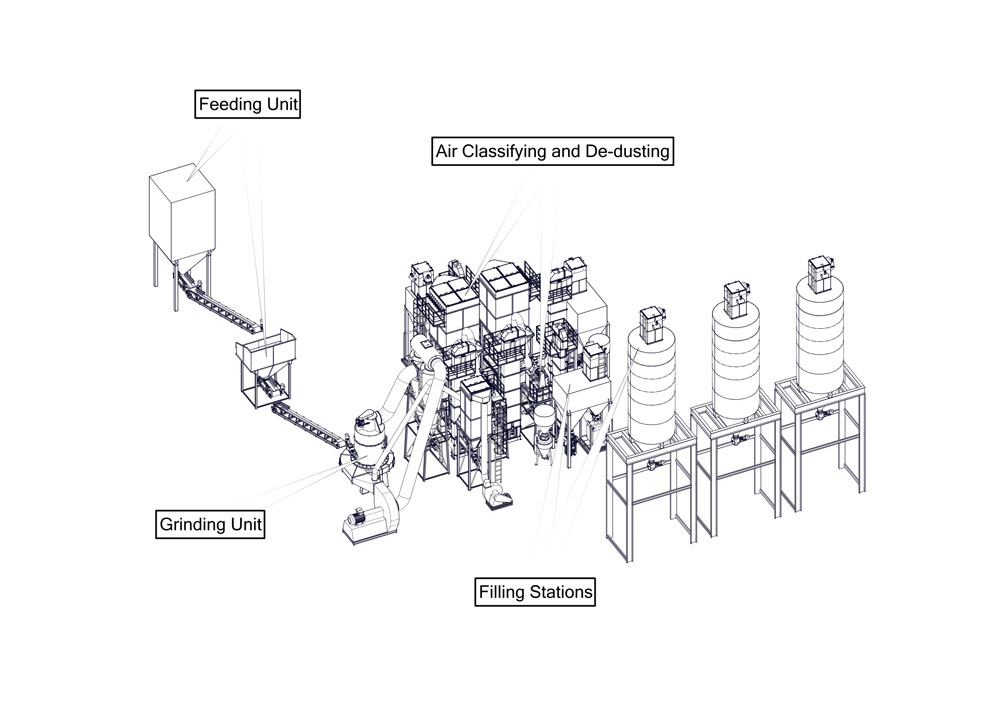

Descriptions about the demonstrated calcite plant;

- Double stage feeding unit transports the material via electronic scale feeder.

- Material ground in pendulum roller mill is transferred to primary turbo dynamic classifier. Classified material passes to secondary turbo dynamic classifier serially.

- Finally, three separate products with different fineness are obtained. Products can be filled by silo truck filling station, big-bag filling station or sack fillers.

- By obtaining three separate products, the process becomes much more flexible for satisfying the requirements of different industries. Upper limits of the product can be adjusted by the variable rotor rpm. of the classifiers and any of the classifiers can be by-passed.

- Automation management is done via central processing computer with SCADA. Process flow can be managed by using a mimic diagram. Simultaneous changes can be made, reports can be obtained, manual controls can be applied. Remote connections are available via ethernet module.